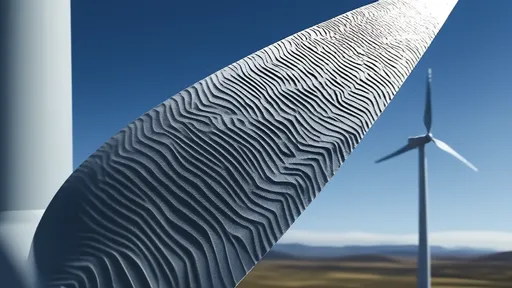

The quest for more efficient wind energy systems has led researchers to explore unconventional solutions from nature. Among these, shark skin-inspired drag-reducing coatings have emerged as a promising avenue for optimizing the aerodynamic performance of wind turbine blades. This biomimetic approach, which mimics the microscopic texture of shark skin, could hold the key to reducing energy losses and increasing power output in wind farms worldwide.

Sharks have evolved over millions of years to move through water with minimal resistance. Their skin contains tiny, tooth-like structures called denticles that manipulate water flow across their bodies. These microscopic ridges create a turbulent boundary layer that actually reduces overall drag—a paradoxical effect that engineers are now adapting for air flow applications. When applied to wind turbine blades, similar textures can delay flow separation and maintain attached airflow over longer portions of the blade surface.

The mechanics behind this technology reveal why it's particularly suited for wind energy applications. As air flows over a conventional turbine blade, it typically separates from the surface toward the trailing edge, creating turbulent vortices that increase drag and reduce lift. Shark skin-inspired coatings disrupt this process by creating micro-vortices that energize the boundary layer, keeping the airflow attached for a greater portion of the blade's rotation. This effect becomes especially valuable during low-wind conditions when maintaining turbine efficiency is most challenging.

Recent field tests have demonstrated the practical benefits of this approach. A German research consortium reported a 6-8% reduction in drag coefficients on coated blades compared to conventional designs. More importantly, this translated to a measurable increase in annual energy production—between 3-5% depending on wind conditions. While these numbers may seem modest, they represent significant gains in an industry where efficiency improvements are typically measured in fractions of a percent.

The manufacturing process for these biomimetic coatings has evolved considerably in recent years. Early versions relied on applying polymer films with embossed patterns, but these proved impractical for large-scale turbine applications. Current approaches focus on developing sprayable coatings that can create the necessary surface texture through self-assembling nanoparticles or specialized application techniques. This allows for retrofitting existing turbines without requiring complete blade replacement—a crucial factor for widespread adoption in the industry.

Durability remains a key challenge for implementation. Wind turbine blades operate in harsh environmental conditions, facing UV radiation, temperature extremes, and particle erosion. Advanced coating formulations now incorporate UV-resistant polymers and ceramic nanoparticles to extend service life. Some manufacturers claim their shark skin coatings can maintain effectiveness for 5-7 years before requiring reapplication, making them economically viable for most operational cycles.

Beyond simple drag reduction, these coatings offer secondary benefits that enhance overall turbine performance. The same surface properties that reduce aerodynamic drag also help prevent fouling from dust, ice, and insect accumulation—common problems that degrade blade efficiency over time. Some formulations even demonstrate self-cleaning properties similar to the lotus effect, where water droplets pick up and remove surface contaminants as they roll off the blade.

The economic implications of this technology could be substantial for the wind energy sector. Industry analysts estimate that widespread adoption of shark skin coatings could increase global wind farm output by tens of terawatt-hours annually. This comes at a critical time when the industry faces pressure to reduce levelized costs of energy while meeting growing renewable energy targets. The relatively low cost of coating application compared to other efficiency measures makes it particularly attractive for both new installations and fleet upgrades.

Looking ahead, researchers are exploring ways to optimize the texture patterns for specific blade designs and wind conditions. Computational fluid dynamics simulations now allow engineers to customize denticle patterns along the blade's length, accounting for variations in airspeed and angle of attack at different positions. Some experimental designs even feature adaptive textures that change shape in response to temperature or humidity variations, though these remain in early development stages.

As with many biomimetic technologies, the shark skin approach reminds us that some of the most elegant engineering solutions already exist in nature. The marriage of biological inspiration with advanced materials science continues to yield surprising innovations in renewable energy. For wind turbine operators facing constant pressure to improve performance metrics, these microscopic surface textures may soon become standard equipment—proving once again that sometimes the smallest changes can create the biggest impacts.

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025