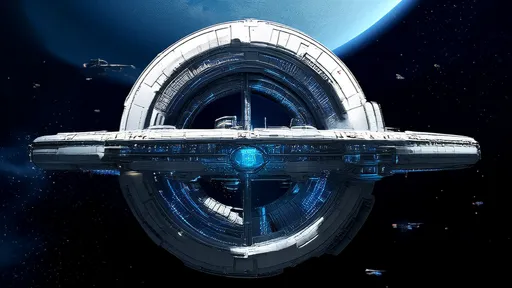

The concept of manufacturing in space has long been a staple of science fiction, but recent advancements in technology and a growing interest in commercial space ventures have brought this idea closer to reality. Among the most promising developments is the emergence of nanofactories in low Earth orbit (LEO), a revolutionary approach that could redefine how we produce materials, components, and even pharmaceuticals. These orbital facilities leverage the unique conditions of microgravity and vacuum to create products that are either impossible or prohibitively expensive to manufacture on Earth.

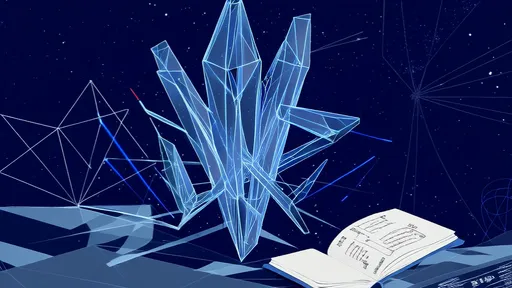

One of the key advantages of LEO nanofactories is their ability to produce ultra-pure materials. In the absence of gravity, sedimentation and convection—two processes that often introduce impurities in Earth-based manufacturing—are virtually eliminated. This allows for the creation of flawless crystals, alloys with perfect molecular alignment, and pharmaceuticals with unprecedented purity. Companies like SpacePharma and Made In Space have already demonstrated the potential of such technologies, conducting experiments aboard the International Space Station (ISS) that yielded groundbreaking results.

The economic implications of orbital manufacturing are staggering. Traditional industries, from electronics to medicine, stand to benefit from materials produced in space. For instance, fiber optics manufactured in microgravity exhibit significantly lower signal loss, which could revolutionize global communications. Similarly, the production of certain proteins and vaccines in zero-gravity environments has shown higher efficacy rates, opening new avenues for medical research. As launch costs continue to decline thanks to reusable rocket technology, the business case for space-based nanofactories becomes increasingly compelling.

However, the road to a fully operational LEO nanofactory is fraught with challenges. Technical hurdles include the development of autonomous systems capable of operating in the harsh environment of space with minimal human intervention. Maintenance and repair logistics present another significant obstacle, as sending technicians to orbit for every malfunction is impractical. Companies are exploring solutions such as advanced robotics and AI-driven diagnostics to address these issues, but progress remains incremental.

Regulatory and ethical considerations also loom large. The legal framework governing space manufacturing is still in its infancy, with questions about intellectual property rights, environmental impact, and international collaboration yet to be fully resolved. The Outer Space Treaty of 1967 provides some guidance, but its provisions are ill-suited to the complexities of modern commercial space activities. Policymakers and industry leaders must work together to establish clear guidelines that foster innovation while ensuring responsible use of orbital resources.

Despite these challenges, the momentum behind orbital nanofactories is undeniable. Private investors and government agencies alike are pouring billions into research and development, betting on space manufacturing as the next frontier of industrial growth. The European Space Agency (ESA) has announced ambitious plans to support in-orbit production, while startups like Varda Space Industries are already building prototypes of their manufacturing platforms. The coming decade will likely see the first commercially viable products made in space, marking the dawn of a new era in human industry.

The environmental benefits of shifting certain manufacturing processes to space cannot be overlooked. Earth’s industrial activities are a major contributor to pollution and climate change, but orbital factories could alleviate some of this burden. By relocating energy-intensive production to LEO, where solar power is abundant and constant, we could reduce the carbon footprint of key industries. Additionally, the ability to mine asteroids for raw materials—a prospect that is becoming increasingly feasible—could further diminish our reliance on Earth’s dwindling resources.

Looking ahead, the integration of artificial intelligence and quantum computing could propel space manufacturing to unprecedented heights. AI-driven design systems could optimize production processes in real-time, while quantum sensors might enable the creation of materials with atomic-level precision. The synergy between these cutting-edge technologies and the unique conditions of space could unlock possibilities we are only beginning to imagine.

The rise of LEO nanofactories represents more than just a technological leap; it signals a fundamental shift in how humanity interacts with the cosmos. No longer confined to exploration and observation, we are on the verge of becoming an interplanetary industrial civilization. The challenges are immense, but so too are the rewards. As we stand at the threshold of this new age, one thing is clear: the future of manufacturing lies not just on Earth, but among the stars.

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025